Accelerating Industrial Device Development with Secure Remote Access

In modern manufacturing, speed isn’t just a competitive advantage — it’s a requirement.

As industries scale up the production of intelligent devices, from IoT modules to complex embedded systems, the challenge is no longer just about hardware. It’s about how efficiently teams can iterate, debug, test, and certify thousands of devices across globally distributed production lines.

This is where secure, temporary remote access changes the game.

The Hidden Bottleneck in Industrial Development

Most industrial environments are structured for physical security and network isolation, which is critical for safety and compliance. But that same structure often slows down the most agile part of the product lifecycle: development and validation.

Without streamlined access, developers and support teams face:

- Delays in debugging devices mid-production

- Limited ability to perform real-time adjustments

- Manual intervention when automation is most needed

The result? Missed timelines. Costly rework. And slower go-to-market cycles.

Rethinking Remote Access — Without Compromising Compliance

The solution isn’t breaking the network perimeter or exposing devices to the public internet. The answer lies in controlled, auditable remote access — deployed only when and where it’s needed.

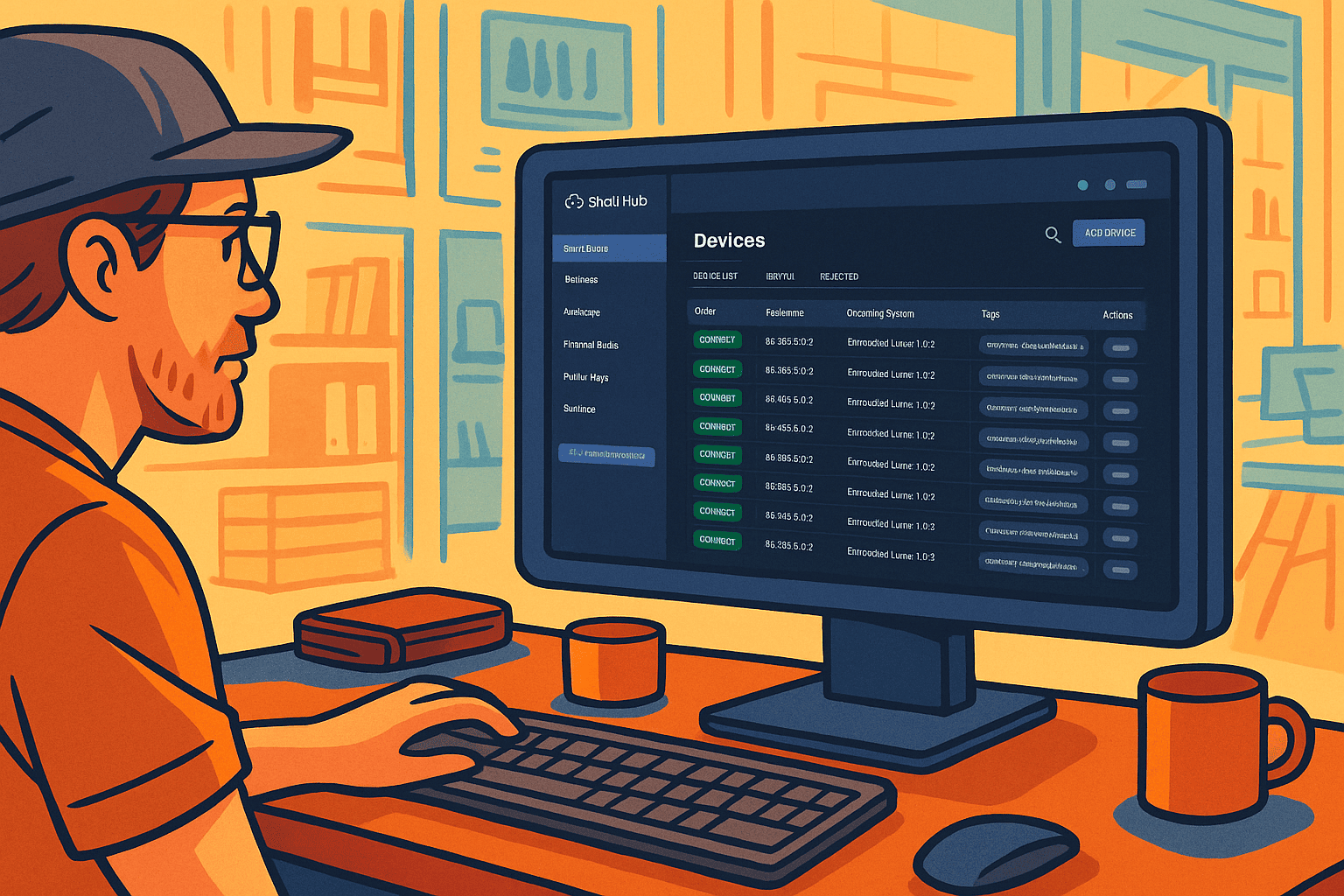

Modern platforms like ShellHub offer a secure and flexible alternative by:

- Embedding a lightweight agent into pre-production firmware

- Connecting over port 443 via secure WebSocket tunnels — no need to open additional ports

- Managing access through namespaces, tags, and public-key authentication

- Enabling automated removal of the agent before certification

In short: you gain access exactly when you need it, and remove it precisely when you don’t.

Development at the Speed of Production

With this model, industrial companies can:

- Reduce configuration time per device from hours to minutes

- Apply batch software adjustments or patches across hundreds of units instantly

- Empower developers to test and iterate in real time, without waiting for physical access

- Maintain strict separation between development and certified production environments

It’s a bridge between agility and security, between development and compliance.

Built for High-Scale, High-Stakes Environments

This approach isn’t just a convenience. It’s a productivity multiplier for companies producing devices at scale.

Whether you're developing:

- Industrial control systems

- Edge computing gateways

- Embedded sensors for energy or agriculture

- Smart appliances or factory-floor electronics

You can dramatically streamline your production cycles without compromising certification, auditability, or security.

Extend Your Toolbox with OTA Updates

Remote access is just the beginning. When paired with solutions like UpdateHub, manufacturers can also manage over-the-air firmware updates, ensuring devices are fully tested, validated, and up to date before leaving the factory.

This reduces risks in the field and increases confidence in every product shipped.

Want to move from bottlenecks to breakthroughs?

Don’t let outdated access workflows hold your production back.

Discover how ShellHub can help your team accelerate development, reduce rework, and stay compliant — all at scale.

? Start your free trial

? Or contact us at contact@shellhub.io.